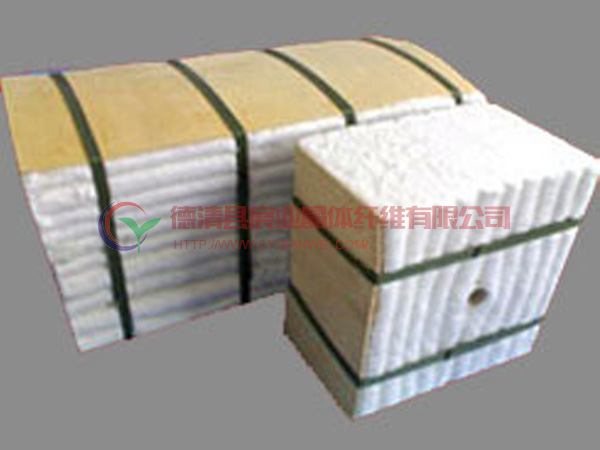

Polycrystalline mullite fiber module

·Low density, low heat capacity, greatly reducing the heating and cooling furnace time

·Low thermal conductivity, effectively saving the cost of the fuel in the furnace

·Good thermal shock resistance

·Anti air scour

·Good mechanical strength

·Inside the metal anchor, safety performance is good

·Simple installation

First, the polycrystalline mullite fiber module features:

·Low density, low heat capacity, greatly reducing the heating and cooling furnace time

·Low thermal conductivity, effectively saving the cost of the fuel in the furnace

·Good thermal shock resistance

·Anti air scour

·Good mechanical strength

·Inside the metal anchor, safety performance is good

·Simple installation

Second, the polycrystalline mullite fiber module application:

·Ceramics industry: shuttle kiln, tunnel kiln, kiln car, etc.

·Steel industry: heating furnace, continuous annealing furnace, kiln car, ladle cover, etc.

·Heat treatment industry: annealing furnace, normalizing furnace, tempering furnace, furnace, kiln car etc.

·Petrochemical Industry: ethylene cracking furnace, conversion furnace, regular / vacuum furnace, coking furnace, flue, etc.

Third, polycrystalline mullite fibers Mo module product classification temperature:

1200-1425 ℃

Fourth, the polycrystalline mullite fiber module product specifications:

1200-1425 ℃ / block

Other special specifications can be customized according to customer

Fifth, the polycrystalline mullite fiber module physicochemical index:

|

Project/name |

CY-1000 Fiber module |

CY-1260 Fiber module |

CY-1400 Fiber module |

CY-1425 Fiber module |

|

Classification temperature (℃) |

1000 |

1260 |

1400 |

1425 |

|

melting point (℃) |

1760 |

1760 |

1760 |

1700 |

|

color |

white |

pure white |

pure white |

pure white |

|

Average fiber diameter ( u m) |

3-4.5 |

3-4.5 |

2.8 |

2.8 |

|

Fiber length (mm) |

~250 |

~250 |

~250 |

~250 |

|

Bulk density (Kg/m3) |

190-240 |

190-240 |

190-240 |

190-240 |

|

texture of material |

ceramic fiber |

|||

|

chemical composition(%) |

||||

|

Al2O3 |

44 |

46-47 |

52-55 |

35.0 |

|

SiO2 |

52 |

51-52 |

44-47 |

49.7 |

|

ZrO2 |

- |

- |

- |

15.0 |